Non-traditional jewelry materials have grown popular in the jewelry industry as titanium and aluminum have become more extensively utilized. For the jewelry circle, born with a high threshold and always treasured for its naturalness and rarity.

Many people find it difficult to believe that non-traditional metals may replace precious metals that have been engaged in the history of jewelry for thousands of years. How did titanium, aluminum, and magnesium, as “newcomers” to the jewelry business, gain popularity? What is their allure?

With inquiries, I’m ready to tell the truth to you!

What is the difference between non-traditional metals and traditional “precious metals”:

Gold, platinum, and silver are stable precious metals suited for producing jewelry.

The reason they are “expensive” is because the mineral resources in nature are modest. This is not the case with the non-traditional metals that are becoming increasingly popular in the jewelry industry today.

Titanium, aluminum, and magnesium are all plentiful metallic elements in the earth’s crust, ranking in the top 10.

Nonetheless, unlike gold and silver, they do not occur in a metallic state in nature, but rather as ores that must be processed into pure metal before being employed as materials for jewelry production.

In the jewelry industry, “18K gold” having 75% gold, “Pt950” containing 95% platinum, and “925 silver” containing 92.5% silver are more commonly used to harden the metal.

Many people saw the moniker “gold” when titanium first appeared in the jewelry world, thinking it also included gold. In actuality, titanium gold does not include gold, but rather titanium metal based on titanium elements.

This is one of the most significant distinctions between the usage of non-traditional metals and traditional precious metals in the jewelry industry.

Titanium is substantially lighter than gold or silver for the same size of jewelry because it has a density of 4.51 g/cm3, which is just one-fifth the density of gold. At the same time, their hardness is higher than that of typical precious metals, thus jewelry created of them is not only not easily deformed, but also does not have to worry about the surface being scratched.

How non-traditional metals became popular:

When titanium, aluminum, and magnesium become more commonly utilized in the jewelry industry, many people will wonder: why can they become popular in the jewelry industry if they are not “precious metals” and their worth is not as high as gold or platinum?

When we go back in history, we can see how a given material or type of jewelry might become popular, either because of a really influential fashion KOL, or because a designer or artist’s subversive “innovative experiments” have been successful.

The latter is undeniably the reason why non-traditional metals have gained popularity in the jewelry industry.

At the end of the 20th century, a group of subversive, highly personal jewelry designers shone brightly in the jewelry world.

In their eyes, jewelry was not only a decoration to be worn, but also a work of art. But at that time, as long as the creation of large Piece jewelry, the inevitable weight is a major problem for jewelry designers.

As titanium and aluminum are much less dense than gold, as long as they can figure them out, jewelry creation will have more room for play. This made a lot of jewelry masters at that time have a great interest.

In the eyes of the artist, art and creation are above all else.

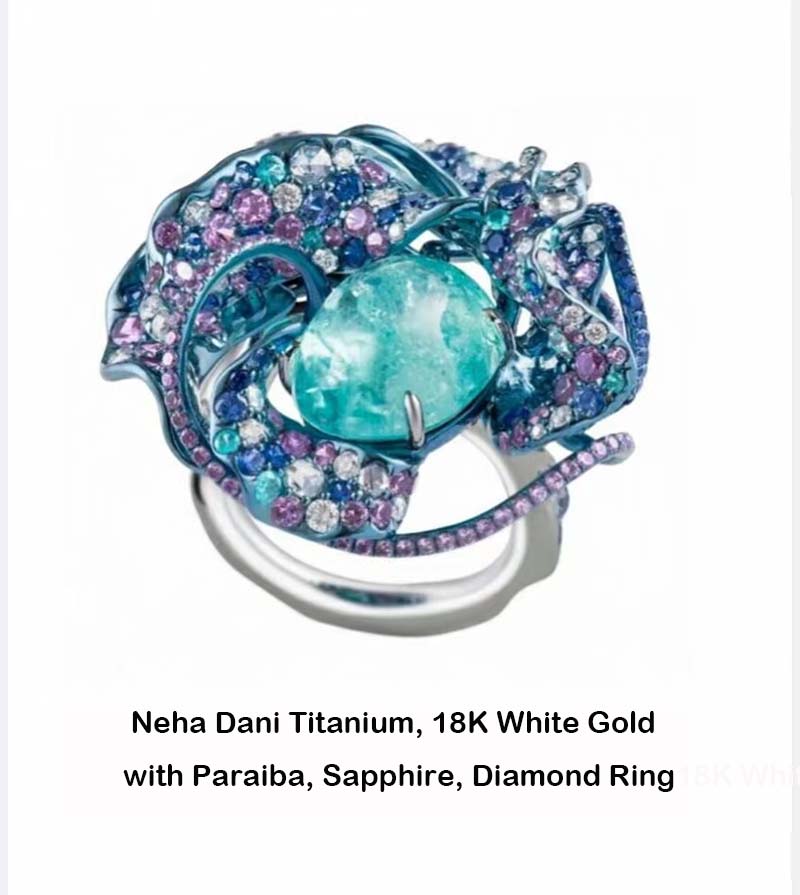

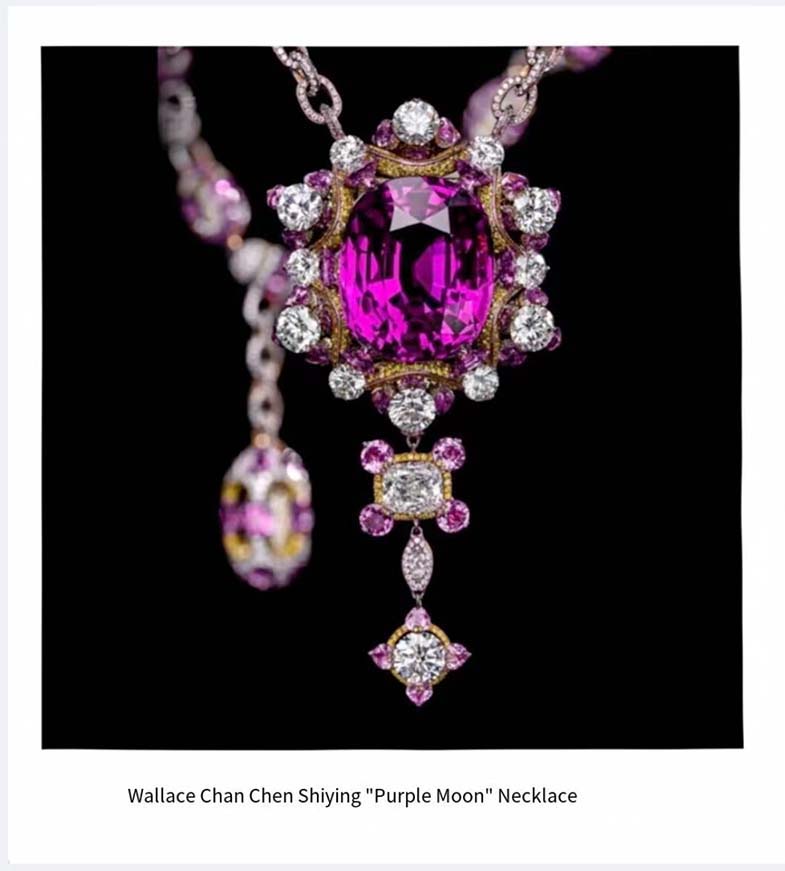

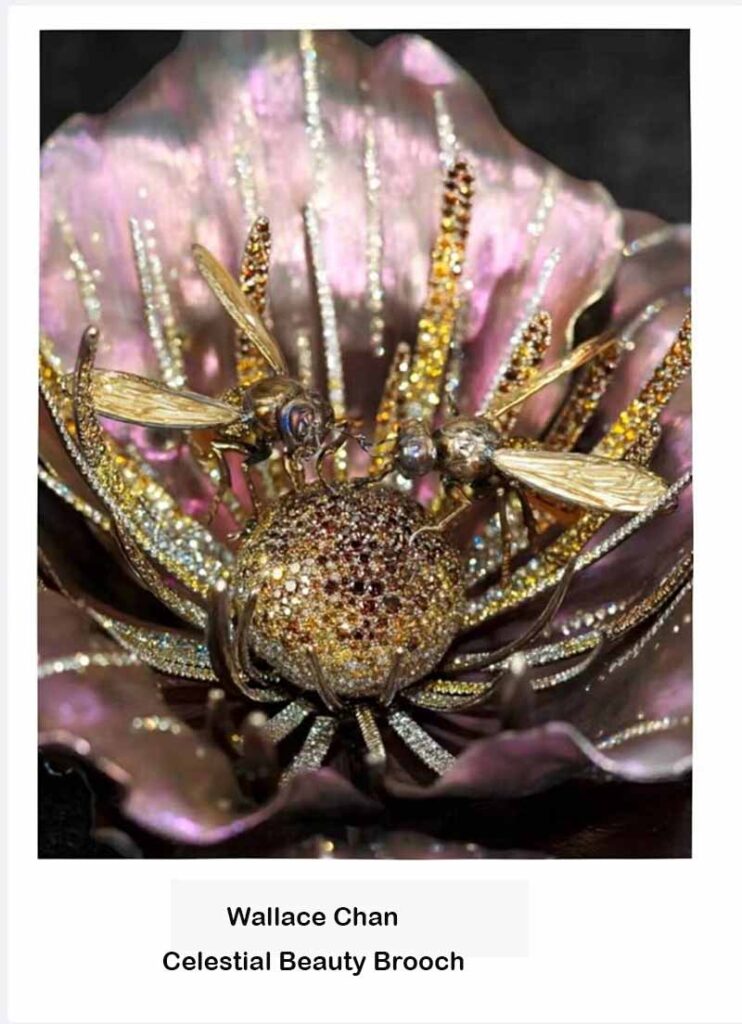

Choosing more appropriate materials is more significant than selecting “expensive” materials. JAR, Wallace Chan, and Cindy Chao were all pioneers in the use of non-traditional metals in their jewelry.

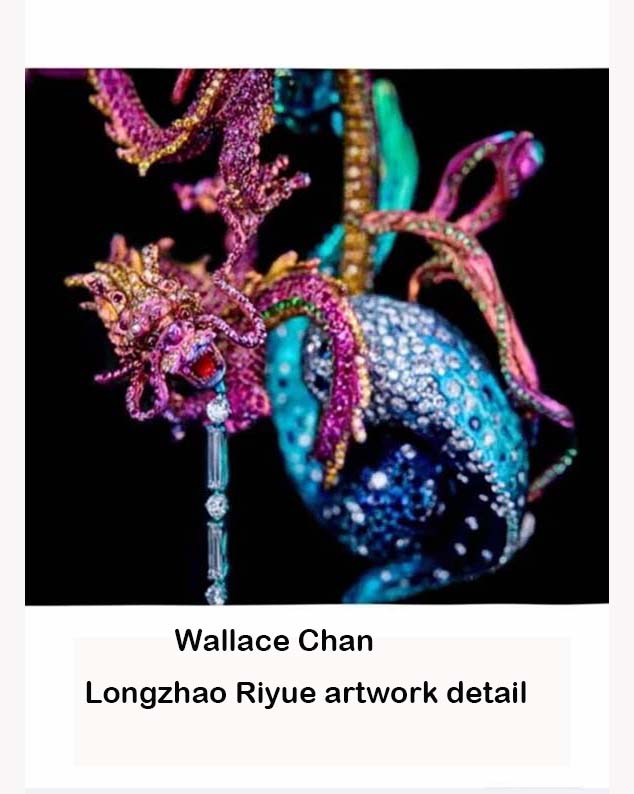

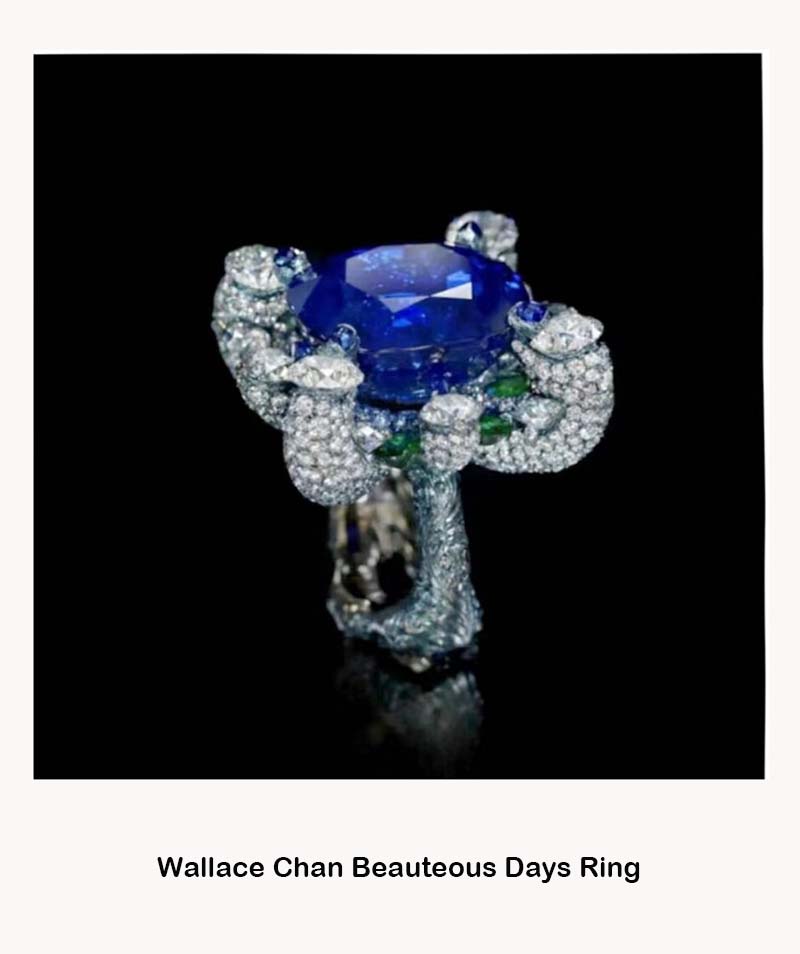

Wallace Chan studied titanium for eight years in order to master the craft of jewelry creation. In 2007, he debuted his first titanium butterfly brooch piece, allowing everyone to witness genuinely lightweight butterfly jewelry.

As more jewelry designers use non-traditional metals, these materials are being experimented with in a wide range of innovative shapes and patterns.

Nowadays, jewelry aficionados are prepared to pay for intricate workmanship, inventiveness and invention, as well as novelty and originality of the creative, in addition to classic costly precious metals.

Titanium, aluminum, and magnesium, which are light and colorful, have also “conquered” an increasing number of individuals.

Titanium, aluminum, and magnesium jewelry are all lightweight and colorful.

What is the distinction between the three in terms of jewelry use? Who do you believe has the most face value? Find out right now!

Titanium metal:

Among the non-traditional metals, titanium is more widely used.

Many people are already familiar with it because of its use by master jewelers.

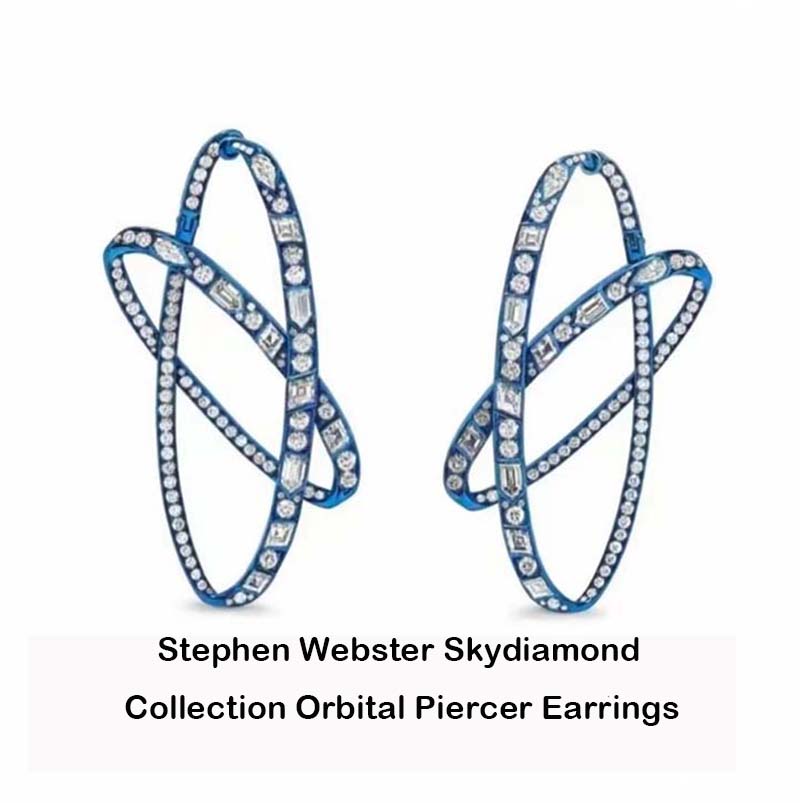

Titanium, unlike white gold, yellow gold, and rose gold, does not need to be fused with other metals to obtain its hue; it may be used on its own!

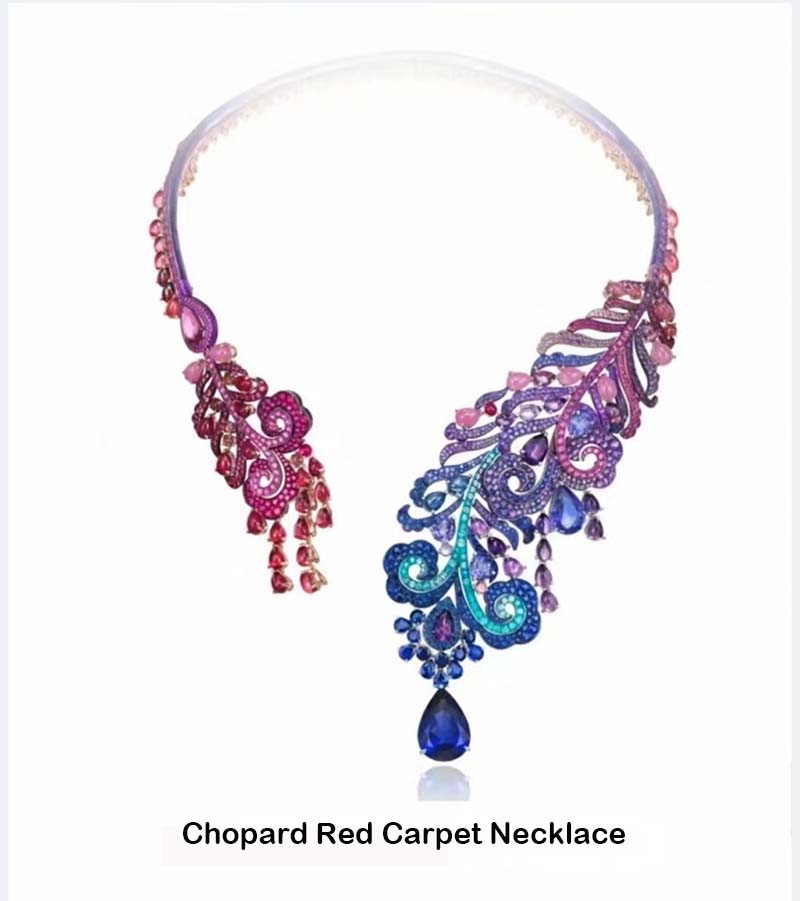

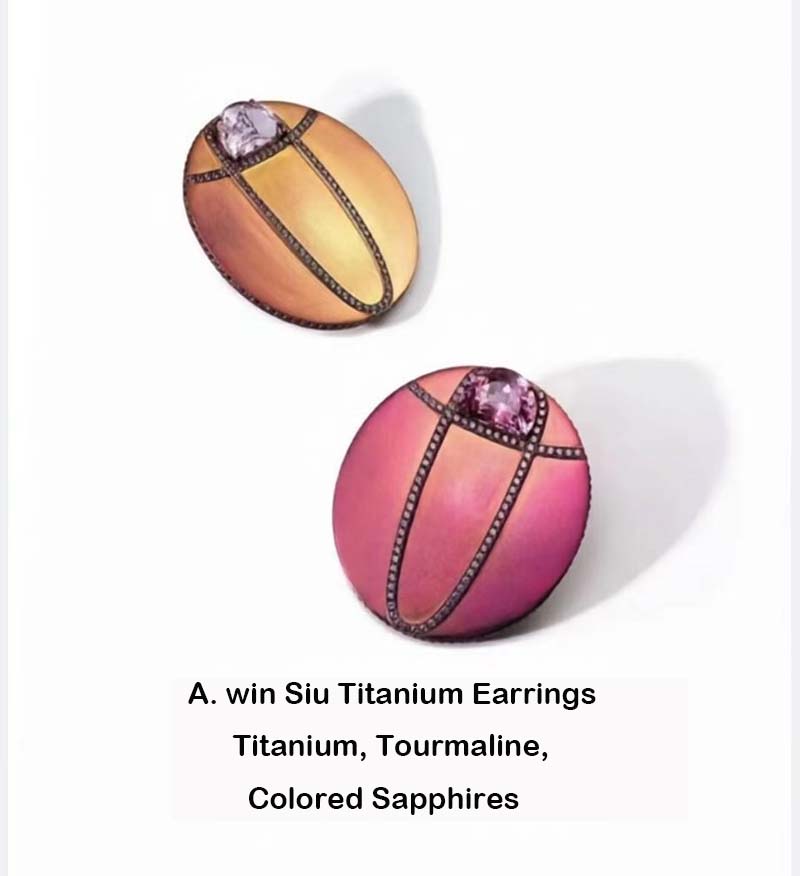

Titanium may take on a variety of hues by oxidizing the surface. Bright azure blue, rich fuchsia, and emerald green are among them.

These are colors that would be unthinkable in conventional jewelry. What’s more amazing is that a single piece of titanium jewelry may have many hues on it, and color gradations are even more intriguing.

Many individuals are concerned that the color of titanium may fade, but there is nothing to worry about. The great majority of titanium jewelry is “colored” by anodizing.

This process produces a thick, transparent oxide coating on the surface of titanium. However, its thickness varies with voltage, resulting in varied hues after light refraction. Because this layer of oxide film is highly stable and difficult to destroy, there is no need to be concerned about jewelry fading.

Titanium jewelry has exploded due to the determined exploration of jewelry makers, each with their own distinct style.

Wallace Chan is eager to provide titanium to wild creativity, as well as titanium and diverse new materials fusion, which will truly be the “future of the metal” known as titanium into a feeling of the future of jewelry.

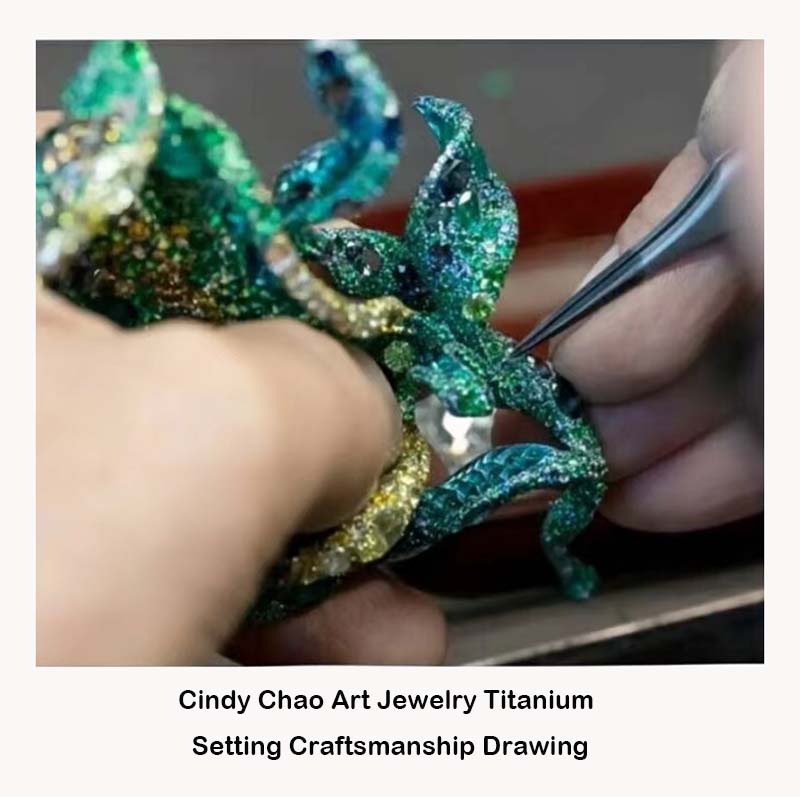

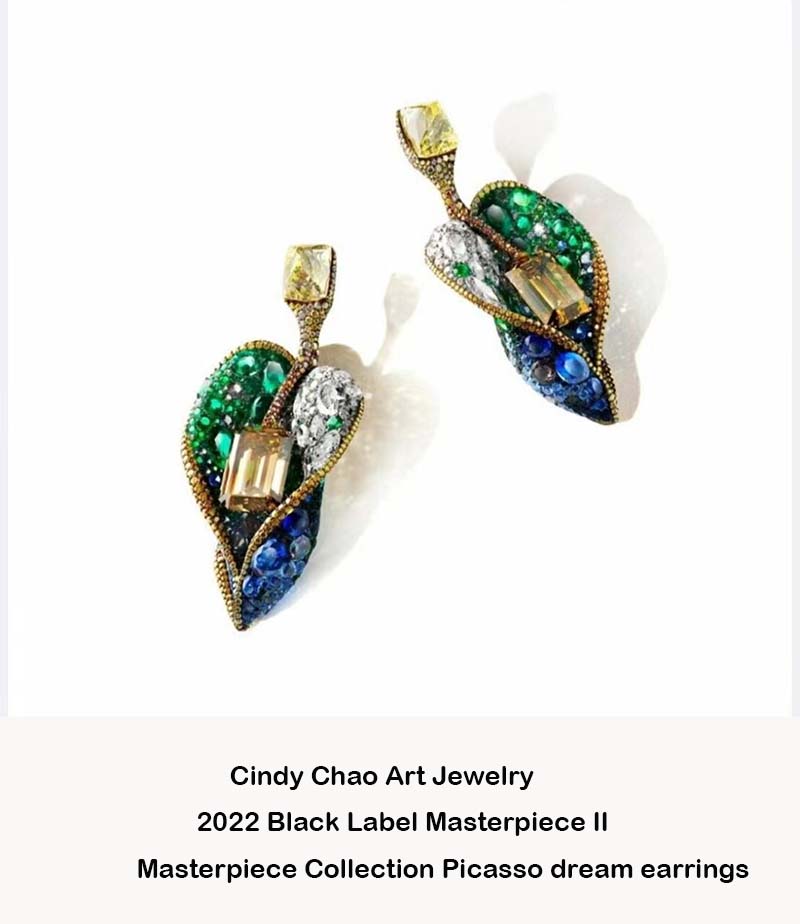

From K-gold claws and titanium diamonds to double-sided titanium inlays, the inlays are regularly improved. Taking up the difficulties of greater workmanship while retaining her own sense of refinement and artistry.

When the world’s niche jewelers gradually overcame the fundamental titanium technology, those “creative” rather than “show off” titanium jewelry became more plentiful!

Numerous specialized jewelers with their own distinctive titanium style have varied new expression, giving us more options in our search of originality.

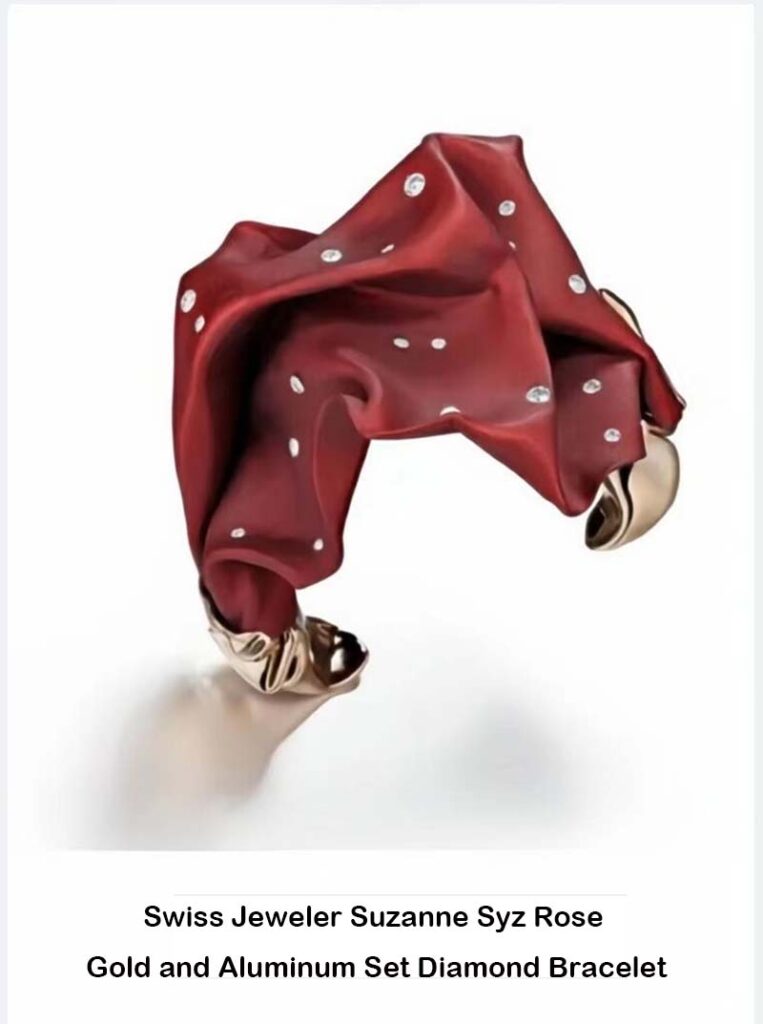

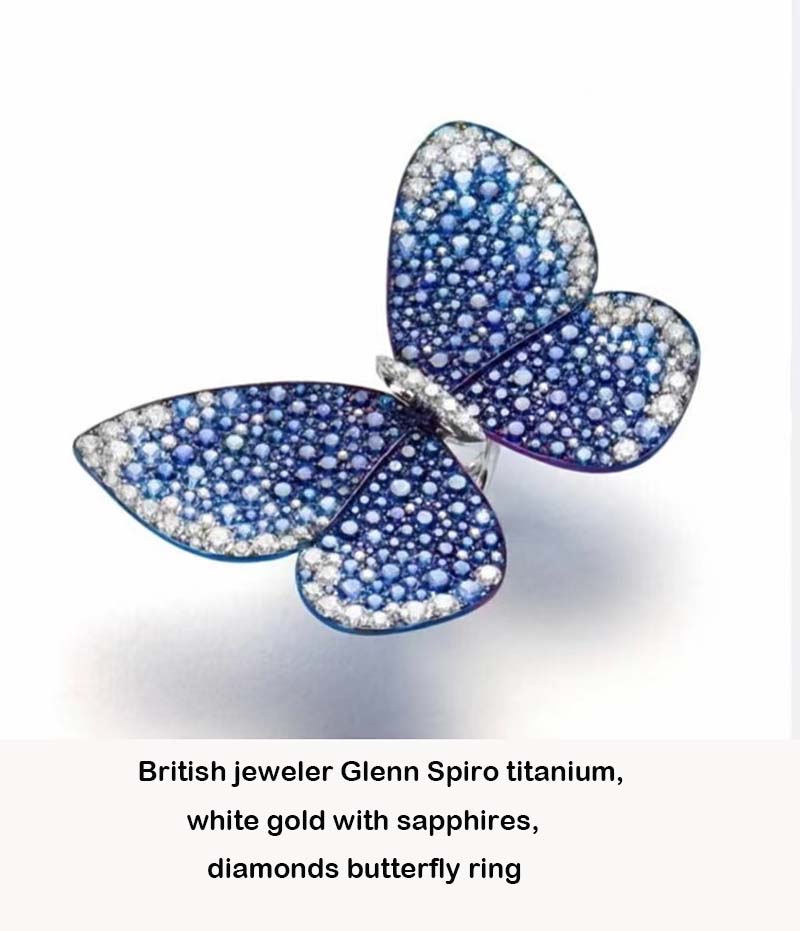

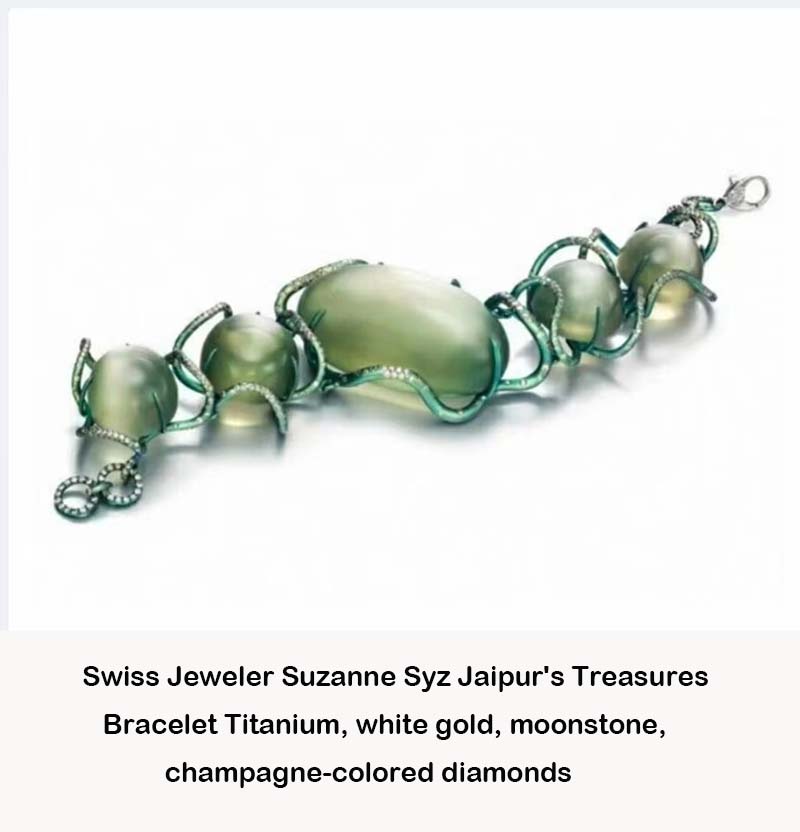

Glenn Spiro, a London-based jeweler who specializes in blending titanium hues with jewels, always manages to make ordinary components appear simple yet elegant. Suzanne Syz, a Swiss designer, is continually thinking beyond the box, transforming titanium into surprising folds, bends, weaving, and geometric forms.

Aluminum metal:

Aluminum metal, in addition to titanium, has become increasingly popular in the last two years. Jewelry businesses, as well as jewelry designers, employ aluminum metal to produce jewelry.

Aluminum is lighter than titanium, with a density of 2.8g/cm3, and it is half the weight of titanium for the same size of jewelry.

The difference between aluminum and titanium is not only in density, but also in color. You will find that most titanium jewelry is very shiny, while most aluminum metal is matte, the color is not as bright, and appears more restrained and textured.

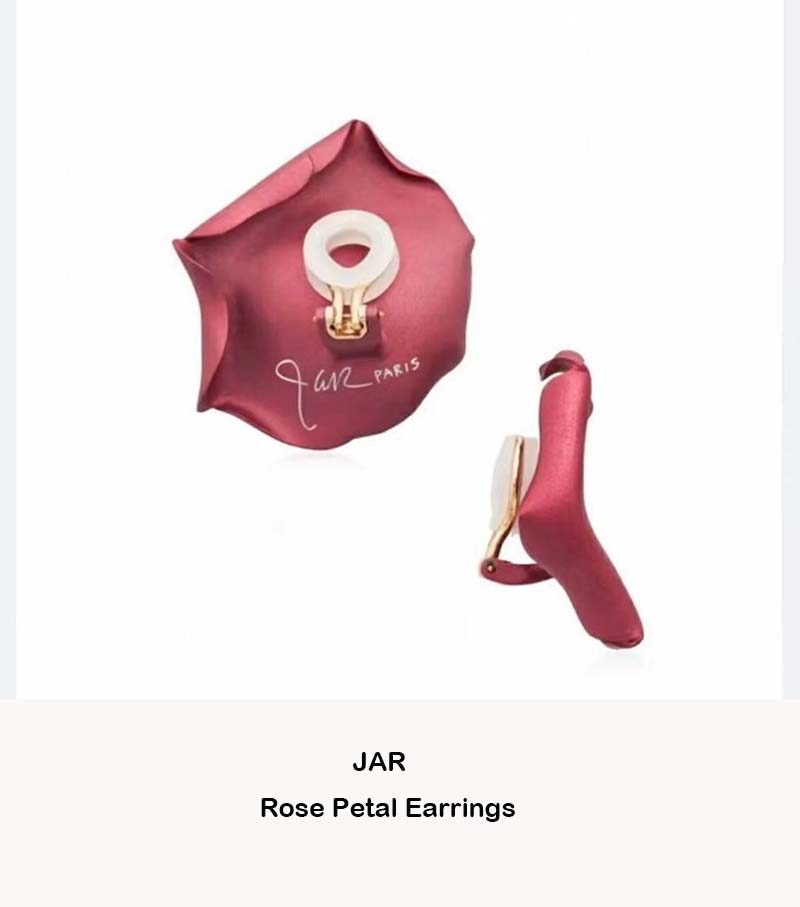

JAR, the master jeweler, adores aluminum, and his famous Rose Petal and Pansy earrings are constructed of it, retaining the petals’ lightness and beauty.

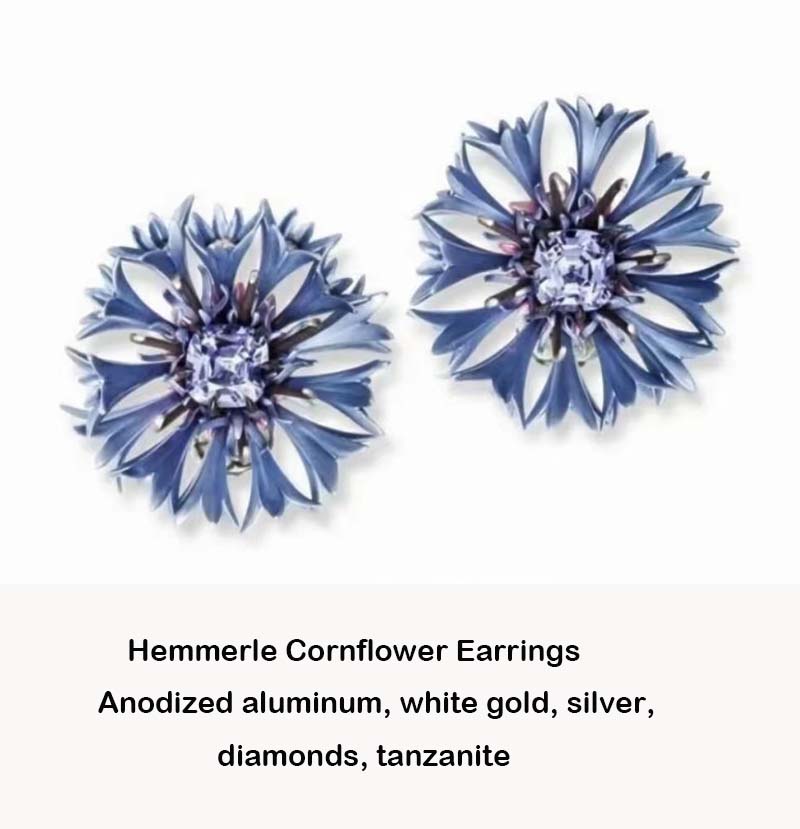

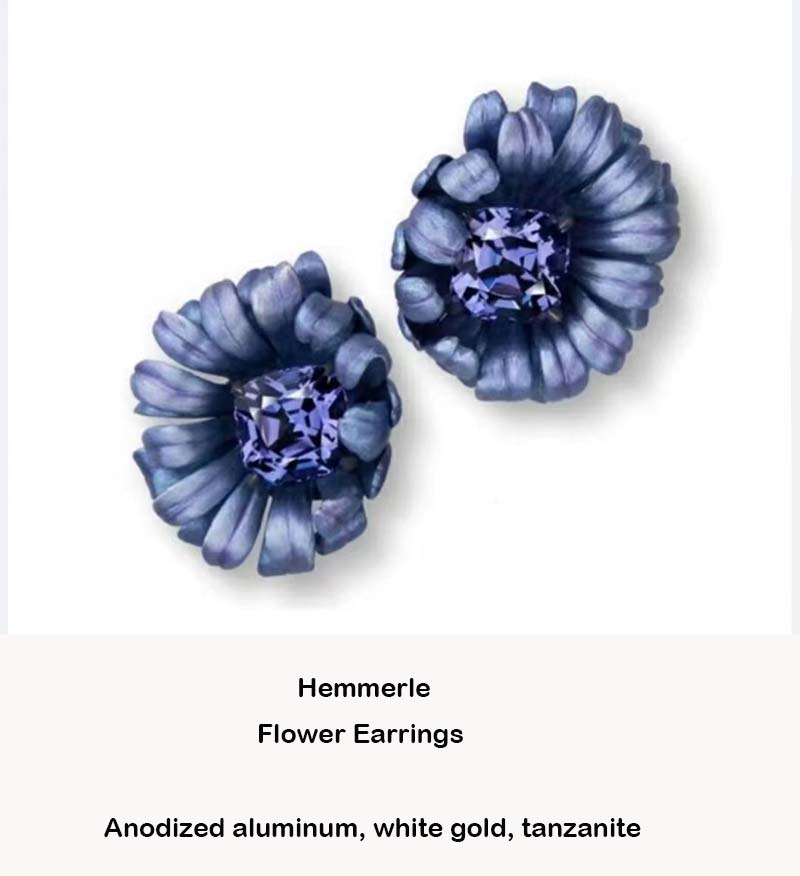

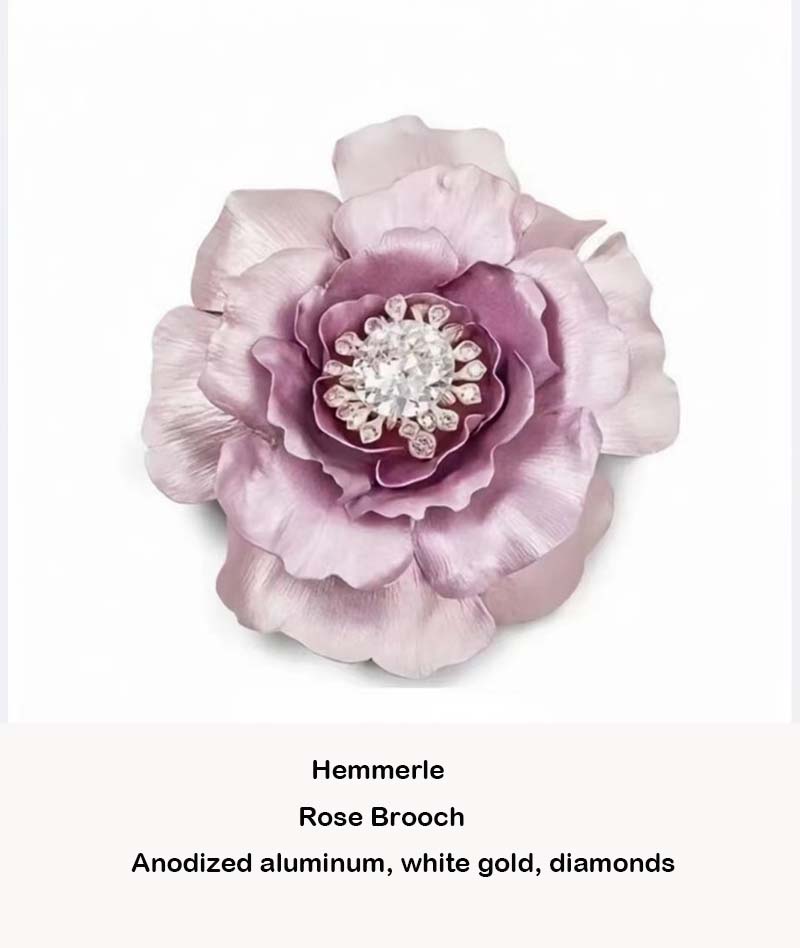

Hemmerle is yet another authority on the usage of aluminum. The German label has long sought natural authenticity. All of their jewelry is manufactured with great craftsmanship and is designed to look like the actual thing.

That’s why they don’t hesitate to use precious materials in their jewelry, often “reproducing” the texture of natural flowers, fruits and other plants in aluminum.

In the hands of Hemmerle’s craftsmen, aluminum can imitate any material: petals, twigs, leaves. Set with magnificent gemstones, the beauty of the stones is complemented by the lightness and authenticity of the natural colors. Bringing the whole piece to life and giving it a more vibrant color palette.

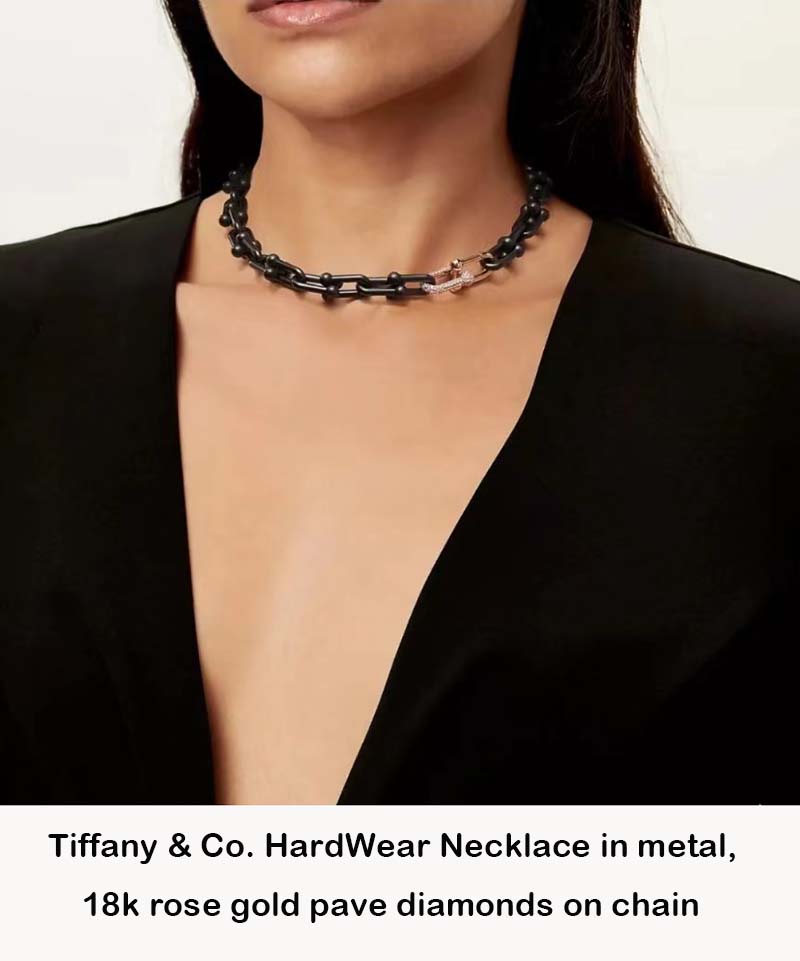

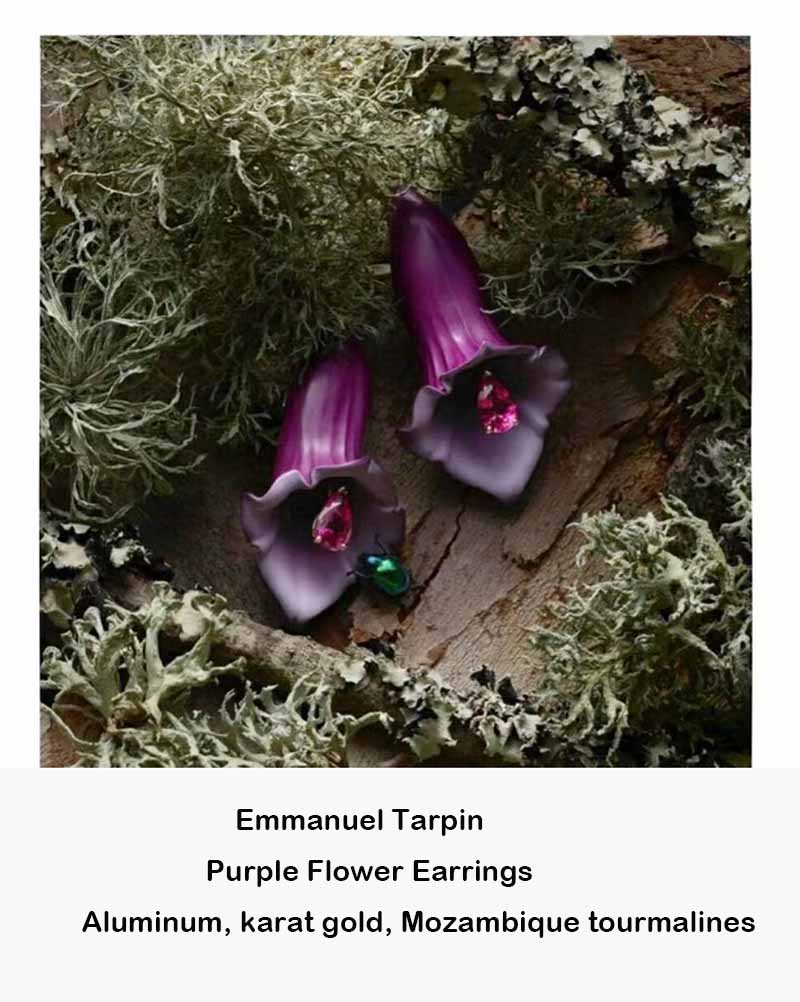

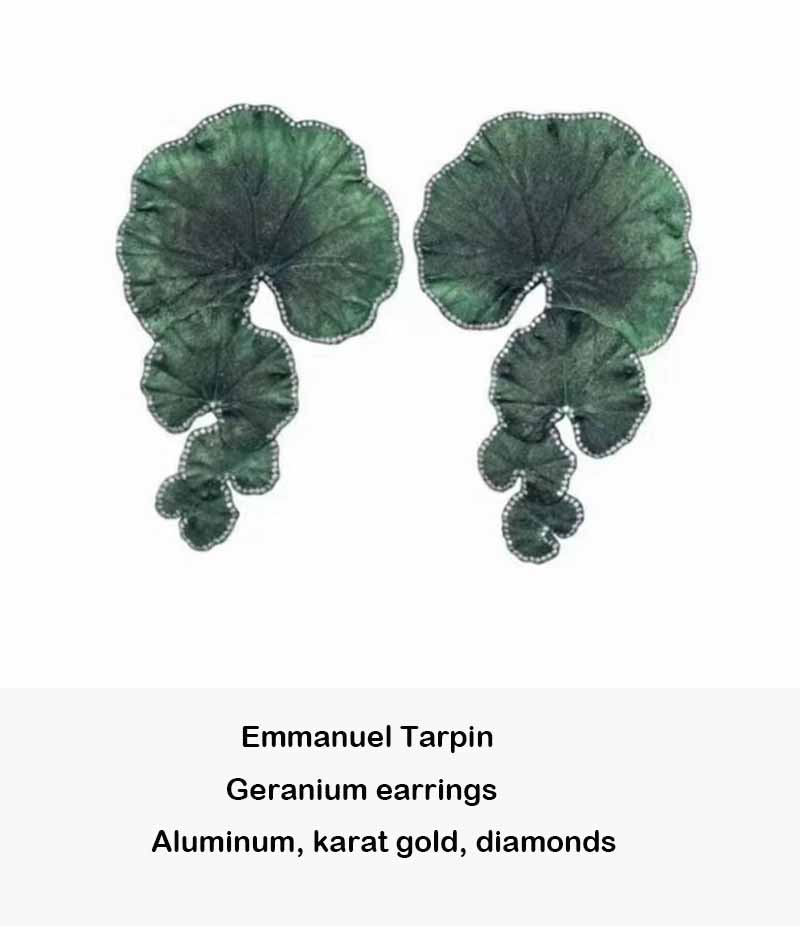

De Beers Jewellers also combines titanium and aluminum to create colorful pieces of fine jewelry that visually represent the two different textures of titanium and aluminum. Among the young designers, French designer Emmanuel Tarpin is also intrigued by the potential of aluminum.

Everything is a contrast,” he says, “from the color gradation, to the polish, to the matte, to the texture of the brushed aluminum, or the shape and brightness of the piece.

I love the feeling of wearing fine jewelry without caring about its weight, because a perfect piece of jewelry must be both precious and wearable.”

His geranium earrings designed with aluminum and diamonds fetched $25,000 at a 2017 Christie’s auction, which catapulted him to stardom in the jewelry world.

Jewelry designer Anabela Chan, who promotes an eco-friendly spirit, also creates some of her pieces in aluminum and uses recycled and refined aluminum from beverage cans, which is quite unusual, but does not detract from the delicacy and splendor of the pieces at all.

Magnesium metal:

Magnesium metal is more niche and lighter than titanium and aluminum; with a density of just 1.74/cm3, magnesium is 30% lighter than aluminum, one-third the weight of titanium, and one-tenth the weight of gold.

It is reasonable to argue that the lightness of titanium and aluminum is sufficient for making jewelry; why would you use magnesium?

This year, Bausch & Lomb, which genuinely employs magnesium to produce high jewelry, offers us the solution with its new Carte Blanche, More is More collection: unless the jewelry is too huge for its own good!

The Tie The Knot oversized bow hairpiece in magnesium is extraordinary. One side comes in a stunning red hue, while the other side includes a black and white striped design. The total item weights only 94 grams. To make this artwork, the artisans had to first design the fine stripes, then electrophoretically paint them black, and then set them.

If the prongs are damaged during the setting process, it is impossible to weld them onto the magnesium, making it extremely difficult to set diamonds in this material. When you look at titanium, aluminum, and magnesium, you will notice that they each have their own characteristics. Jewelry has more possibilities and artistry because of them. What other unexpected creations will these unconventional metals create in the future?

Will more metals be used in jewelry making?